Warehouse automation is an important component for a productive, cost-effective business. Customers do not want to wait, and you need to keep up with the competition. Warehouse automation is the perfect solution for reducing costs and becoming more efficient than your biggest competitors.

What Is Warehouse Automation?

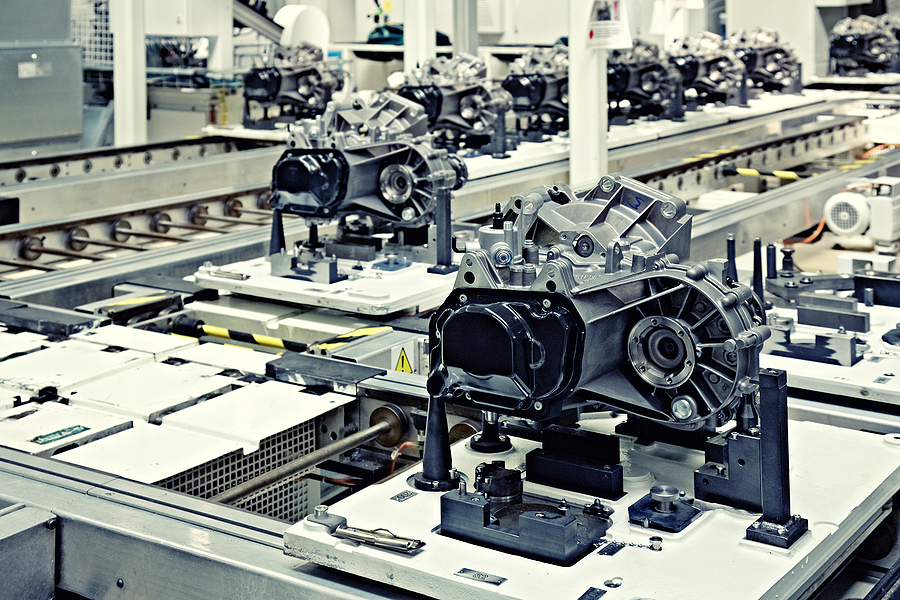

Technology has come a long way. Today, there is artificial intelligence being used more and more. Robotics and equipment like automated guided vehicles (AGVs) and built-in analytics (back to AI) keep orders fulfilled and inventories managed with precision. Warehouse automation embraces all of this.

The goal of warehouse automation is to be as efficient and accurate as possible using all of this technology. When it works well, you gain multiple benefits.

- Better Employee Advancement Opportunities: Employees have the opportunity to learn coding, AI technology, and debugging skills, all of which are valuable when it comes to career advancement.

- Enhanced Workplace Safety: Robots don’t get tired, need breaks, or suffer from aches and pains that lead to accidents in the workplace.

- Improved Accuracy: With AI technology continually scanning output to make sure it’s an exact match to the product requirements, accuracy improves. That means less waste and product recalls.

- Increased Efficiency: Automation can pick, pack, and ship items at much faster rates than humans, which means products are ready to ship much faster than usual.

- Reduced Labor Costs: You won’t need as many manual laborers. Keep your dedicated workers for new roles and provide the training they need. If required, scale down on workers who weren’t pulling their weight. You save money on benefits and no longer need to mandate overtime during busy periods.

- Scaled Operations: You’re able to grow your warehouse operations without needing to hire a lot of new workers.

Tips for Choosing the Right Robotics, Automation, and AI Solutions

Your warehouse will need customized solutions to become fully automated. It’s not a one-size-fits-all model. The key to a successful automated warehouse lies in figuring out your specific needs and how technology can help with them. These are the questions to ask your team as you automate your warehouse.

What’s Our Maximum Budget? How Much Are We Hoping to Invest in Automation?

There’s no point in moving forward until you have a clear budget in mind. This will likely be determined by how much cash you have available to invest, what business improvement loans you’ve been preapproved to get, and any grants you’ve applied for and received.

Once you have a maximum budget, you can start narrowing down what you can afford to start with. To do that, you have to have a plan in mind on where you want to invest that money. Factor in the expected return on investment (ROI) as the added revenue you gain helps you pay back any loans faster.

Mitsubishi Electric can help you understand the best ways to put the budget you have to work. And, we’ll offer insight on what you should invest in the next time you have money available. It doesn’t have to be an all-at-once approach. If self-guided forklifts are more important to start, make that a priority. If you’re not sure, don’t worry. That’s why there are warehouse automation experts ready to help you.

What Is Our Current Order Volume for the Products We Handle? Do We Plan to Expand?

What are you currently storing in your warehouse and shipping to customers? How much space do those products and shipping supplies take up? You’ll need to have space for automation, so you need to make sure you have the room. If you plan to expand in the next few years, factor in your expansion plans, too.

How Much Space Do We Have?

If space is tight, you need to focus on robots, conveyors, and other systems that fit the area. This might mean completely redoing your warehouse’s layout. If you do have to remodel your floor, make sure you have room for the shelving and storage that’s being moved to another area.

You may need to expand your warehouse first and then circle back to warehouse automation. If that’s the approach you need to take, consider the automated equipment you want to add when you’re calculating how large to grow. This helps you scale down where it’s appropriate or size up if there is robotic equipment or conveyor systems you cannot live without.

Choose a Well-Rounded Approach

Robots are a big part of warehouse automation, but they’re not the only aspect. You need a well-rounded approach to moving to warehouse automation. Robots are great, but they need instructions to do their job. Warehouse management software (WMS) is just as important.

AI is one of the best ways to have your warehouse’s daily routines, output, and inventory continually studied to find better, faster, more efficient ways of doing things. With WMS, you have a warehouse that’s working at the optimal pace without wasting time or product. Consider these aspects of software that cannot be ignored.

Maintenance and Updating:

Not only do you need to stay on top of system updates, but your equipment needs regular maintenance to keep it working like new. If you often forget to check for and install updates, have an IT team who are taking care of that for you. Maintenance also ensures that your new equipment lasts as long as you expect or, hopefully, even longer than you could ever imagine.

Scalability:

Your business will grow, but you can control how much. As it does grow, make sure you’ve chosen equipment and software that are flexible and match your needs as your business expands.

Training:

Your employees need to be trained on how the software and equipment works. They have the expertise that your AI systems need to analyze and learn from. As the move from warehouse employees to automation may cause panic among your workers, make sure you make it known they will not be replaced. They have the opportunity to grow into new roles and develop vital new skills they can take with them.

Understand the Future of Warehouse Technology

With consumer demand for products faster, while also wanting quality, problem-free items, warehouse automation is a practical solution. Become efficient without sacrificing quality or driving up prices. Position your business to be competitive while also being able to achieve sustainable growth and high profits.

Mitsubishi Electric is a leader in warehouse automation, robotics, and AI. We have the equipment and technology you need to have a fully automated warehouse that does more than you could imagine. Reach us online or by phone to discuss what you want to achieve, and we’ll deliver a thorough plan that ensures you meet those goals.

Work with Us and Succeed

We love our customers and the challenges they bring to us. We also like to let our customers shine by discussing how we worked together to solve their biggest challenges. If you have a challenge that needs to be solved and would like to be our next BIG success story, reach out to us and let’s connect!