Staying Competitive with Modular CNC Programming

Chad Braid has good reason to be proud of his family business’s success. As Vice President of Operations for Full House Machinery, Braid estimates that “about a quarter of the residential and commercial wood doors in the U.S. come off of our machines.” That’s an impressive statistic in a growing North American market worth over $31 billion each year.

Full House has built a solid international market position since Braid’s father founded the Florida-based company in 1981. But after several decades of good performance, the three Braid brothers who now run the business found themselves at a crossroads.

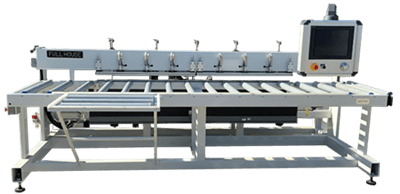

“We manufacture capital equipment for pre-hanging doors,” Braid explains. “Our machines take in a door slab, cut routes for the hinges, create openings if the design calls for window lights, add the frame and apply the hinges. Basically, the machines we make take a base door slab and transform it into what you’d see in a Lowe’s or Home Depot.”

Their machines rely on CNC manufacturing processes to turn out finished doors with consistency, accuracy and fast through-put. The problem for Full House and their customers was that the current CNC control system was fast becoming obsolete.

Staying Competitive with Modular CNC Programming

With their existing PC-based system, programming a finished machine was cumbersome and time-consuming, “It was almost like starting from scratch on every machine,” Braid says. “It would be weeks of troubleshooting, and a lot of times you would get a machine out to the customer and have to send someone out to do even more programming, reprogramming and debugging.”

The last straw was being at the mercy of multiple vendors. Their control systems supplier, Braid recalls, “really wasn’t manufacturing anything themselves. They had no control if something got discontinued. They were at the mercy of ten different vendors.”

Fortunately, one of those vendors was Mitsubishi Electric Automation, Inc. Mitsubishi Electric SoftGOT GUIs and micro-PLC controllers had been included on Full House machines for over 10 years. In fact, Full House had gradually been migrating to more and more Mitsubishi Electric components. When Mitsubishi Electric sales representatives proposed a single-source solution, Braid was more than open to the idea.

The proposed control system combined Mitsubishi Electric Q-Series PLCs and GOT2000 HMIs, plus single-, dual- and three-axis drives and motors with a C70 Series CNC Controller. It would enable Full House to offer a much more user-friendly system to their customers.

The C70 controller integrates CNC motion into a multiple CPU Q-Series PLC backplane, allowing everything to be housed in the same rack and to communicate seamlessly. As a result, the entire control system can share and monitor all of the machine I/O from a single access point. The C70 also offers the ability to control up to 16 axes, a major upgrade over their old single-axis PC control system.

The “CNC Edge” is one example of a Full House machine. Its 3-Axis Motion Controller allows quick processing of the hinge side, lock side, top and bottom of a door blank.

Implementing modular programmingThe new system’s biggest advantage for Full House is the opportunity to use modular programming, which Braid estimates cuts several weeks to a month off the commissioning of a new machine. “It just speeds up the whole process of programming. This system has allowed us to take a pre-written program and just plug it in. It works immediately. And Mitsubishi Electric has been great with helping us develop the programming.”

Modular programming is the process of splitting a computer program into discrete sub-programs, called modules, that can be coupled together. Base modules include the computer processor, input connections, and electrical power regulation. Supplementary modules might include analog to digital signal converters, additional outputs and other functionalities.

Modular devices are easier to repair, have advanced memory, and have the capability to store high volumes of data. In addition, they provide automation solutions which include seamless interoperability plus greater system stability and reliability.

As a general rule, about 80% or more of new machine tasks reflect some variation of past tasks. By using and modifying existing software modules, programs for a new machine can be generated much more quickly, and each module can be modified to meet new requirements.

How much time does this modular capability now save Full House? “It varies,” Braid cautions, “because every machine we build is custom. But I would say we’re doing our programming in 25% of the time, so we’ve reduced commissioning time by 75%.

Responding under pressureThe new control system technology and its easier programmability is one thing, Braid says, but he contends that the strong relationship between Full House, Mitsubishi Electric and Diamond Elite Distributor HPE Automation has been even more essential to the system’s success. As an illustration, he cites the installation process for the first C70-equipped customer machine in Las Vegas.

“I think that was basically a big turning point as to everybody getting involved and saying, ‘Hey, we’re doing this as a team,'” Braid recalls. “That trip was huge because it got HPE, Mitsubishi Electric and our guys all together on an installation to work through any potential issues.”

He notes that there was no time or resources available for a drawn out R&D program. “It wasn’t a two-year development process. It was ‘This is sold. Let’s make it happen.’ It had to go to a customer and get to work, so it was a real pressure cooker situation.” In the end, he adds, the new machine was commissioned and up and running in record time.

Moving to the Mitsubishi Electric control system not only saves time, it has also opened up new opportunities for Full House. “We’re definitely way more competitive,” Braid says. “Our target customer base has changed to include larger manufacturers. We have the ability to sell bigger fish now. They’ve taken notice and we’ve made some sales in new markets.”

Building relationships

Along with the C70 controller, the new system includes GOT2000 HMIs, which enable customers to easily reprogram their own machines. Braid explains, “Our customers like how user friendly the system is. They love the flexibility of it. They can make it do what they want it to, as opposed to having to call us and us write a new program. The Mitsubishi Electric system makes it very easy for our customers to change offsets or to tweak programs, without having to know coding.”

Full House engineers have more flexibility, as well, because they aren’t tied up for weeks commissioning and troubleshooting new machines. “They love that they can go out now to do a setup and spend less time fixing and tweaking the program. They can spend that time training the customer,” Braid says.

In addition, the C70/GOT2000-based solution eliminates the need for an onsite computer and cable to troubleshoot or monitor the system. In fact, Full House engineers can now monitor and service a machine from almost any location. “Our guys can operate a customer’s machine over the Internet. That makes it much faster and easier to diagnose problems or upload and test a new program. That isn’t something we were able to do before.”

Summing up the relationship with Mitsubishi Electric, Braid says, “They really, really make it feel like we’re a team, and we’re all in it together. If ever there’s an issue, they have our back. They’ll use their resources to help us solve any problems or ramp up any new projects. I’m confident that Mitsubishi Electric will do anything in their power to help me out when I need it. They’re always there to help.”

Become Our Next Success Story

We love our customers and the challenges they bring to us. We also like to let our customers shine by discussing how we worked together to solve their biggest challenges. If you have a challenge that needs to be solved and would like to be our next BIG success story, reach out to us and let’s connect!