Industrial networks enable communication between elements of a control system. These include sensors, valves, motors, pumps, drives and much more. Control communications can have impacts on performance, quality and reliability. In addition, control devices or the controller itself play an important role in information gathering to support layered analytics – HMI, SCADA, AI, ML, etc. The selection of an industrial network is pivotal to creating the most competitive machine, production line or process.

Selection criteria to consider for choosing an industrial network:

- Performance – both in speed and determinism

- Reliability – supports redundant or ring architectures

- Medium – optical, wired, wireless

- Connections – Ethernet vs. proprietary or other connector standards

- Convergence – able to coexist with multiple protocols

- Open – supported by third-party vendors

- Proven – globally registered standard with history of adoption and use

- Embracing – able to integrate devices with other protocols through converter use

- Supports Standard IT Tools – SNMP for device management and troubleshooting

Performance – The need to consider performance in an industrial network will vary greatly with the size of, and character of the application. Small applications will have fewer devices and can tolerate lower communication bandwidths. Motion control applications will likely need higher performance communications and even deterministic (fixed schedule or prioritized) communications. Bandwidths are now less of a consideration as in the past, and gigabit Ethernet is becoming more common. In addition, new technologies such as Ethernet with TSN (Time Sensitive Networking) can be a consideration.

Reliability – supports redundant or ring architectures. The proper architecture can deliver tolerance to communication failures, either using redundant communication paths, or ring architectures that can deliver continued control in the event of a break in a communications link. Star architectures are also important, in their ability to isolate communication segments from one another.

Medium – optical, wired, wireless. Your choice of medium will largely depend on the operating environment. High electrical noise environments or applications that require electrical isolation will benefit from optical fiber communications. Applications with mobility requirements such as AMR (Autonomous Mobile Robots) or crane systems would benefit from wireless communications. Wired applications are still the default and likely the most cost-effective solution.

Connections – Ethernet vs. proprietary or other connector standards. In industrial networks, the Ethernet connection standard is becoming the most dominant connection type. However, environment requirements for water or dust protection may define other connection types, like the use of circular connectors, M12 and M8 being two of the most common for industrial settings.

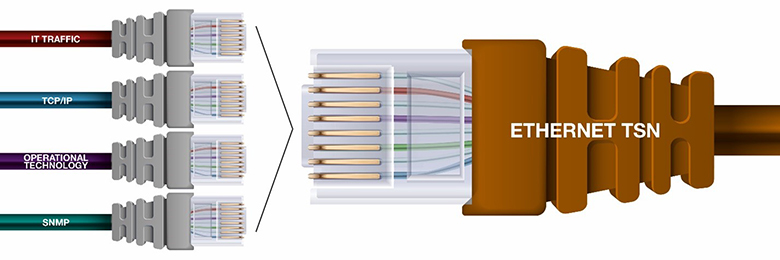

Convergence – able to coexist with multiple protocols. In the world of Ethernet communications, it is common to find many types of communications and conversations coexisting on the same cable. Modern Ethernet switches can streamline traffic on networks and help to improve communications speed, but Ethernet is inherently a “best effort” form of communications and is non-deterministic. Efforts have been made by some vendors with token passing or other techniques, to manage Ethernet communications for use in applications that require determinism, however when other, unknown traffic is present, determinism becomes more challenging. Increasing bandwidth, going from 10mb to 100mb or 1gb connections can help, but selecting communications that leverage TSN (Time Sensitive Networking) will let you prioritize critical communications and ensure that they will not be impacted by general purpose communications. You can then enjoy the benefits of a converged network – simpler architecture, easier troubleshooting and reduced costs.

Open – supported by third-party vendors. Some industrial networks are closed and limited to only devices from a single vendor. Ideal architectures will leverage open networks with support by many industrial automation product vendors.

Proven – globally registered standard with history of adoption and use. The most widely used networks have been made open, to be widely adopted by industry, and have also been registered as IEC (International Electrotechnical Commission) Standards. These standards are proven and well adopted in industry.

Embracing – able to integrate devices with other protocols through converter use. No single company can offer all products that an application or market may need, and no one protocol is supported by all devices. Protocol Converters exist to bridge devices with one protocol to a network with another protocol. You should be sure that the Industrial Network that you have selected also is supported by Protocol Converters, giving you the broadest potential set of devices with which to build your applications.

Supports Standard IT Tools – SNMP for device management and troubleshooting. If an Ethernet backbone has been selected, then the devices you are using may also support standards common to the IT (Information Technology) market. SNMP (Simple Network Management Protocol) is the most common IT resource for monitoring and managing devices on a network. SNMP is becoming more commonplace in Industrial Networks and is a common attribute of some Industrial Network Protocols.

In conclusion, the selection of an industrial network is a crucial decision that can significantly impact the performance, quality, and reliability of a control system. By considering various criteria such as performance, reliability, medium, connections, convergence, openness, proven track record, compatibility with other protocols, and support for standard IT tools like SNMP, one can create a competitive and efficient system. The choice of medium and connections will depend on the operating environment, while embracing other protocols and supporting standard IT tools will ensure a more comprehensive and versatile system. Ultimately, the selection of the right industrial network will enable the effective coordination of various elements in a control system, leading to better performance and overall success. Mitsubishi Electric offers a variety of Industrial Network options, including the support of third-party protocols.

Work with Us and Succeed

We love our customers and the challenges they bring to us. We also like to let our customers shine by discussing how we worked together to solve their biggest challenges. If you have a challenge that needs to be solved and would like to be our next BIG success story, reach out to us and let’s connect!