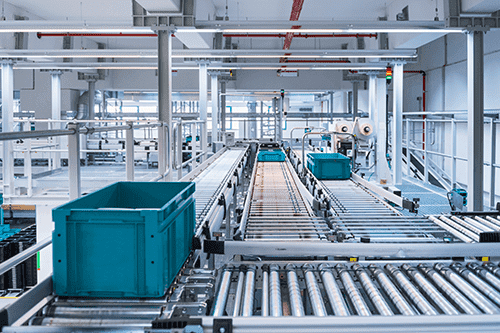

Sorting disparate sized packages requires high-speed networking to databases, fast response in servomechanisms, and highly tuned controls to ensure diverter trays and conveyors are well coordinated. Today’s postal, freight, and warehouse e-commerce systems are rapidly changing the requirements for servo, VFD, and PLC technologies. As new industrial material handling equipment communication technologies emerge to interact with cloud-based inventory and sortation algorithms, the iQ-R series controllers have evolved to provide the utmost in response and data integration for automated material handling systems. Moreover, smaller parcels and next day deliveries have forced many companies to rethink sortation models and automatic material handling systems in order to reduce labor costs, freight costs, and damage rates.

Automated fulfillment centers now require on-site sortation and rapid fill rates that require highly responsive controls and automated pick and pack operations including automation conveyor systems. Mitsubishi Electric provides the material handling solutions necessary to handle these tasks.