FR-E800 Compact Inverter Preview

Here is the text to describe the video and the features of the new FR-E800 Inverter.

SmartMachines

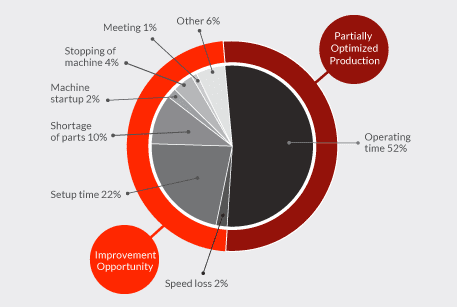

Analyzing production or fulfillment anomalies and machine shutdowns can be a challenge without robust information and operator intelligence.

Put critical production information at your fingertips with Smart Machine technology.

Mitsubishi Electric’s built-in troubleshooting screens pull production and diagnostic information from its servos to provide the critical tolerance and availability data necessary to avoid unexpected production losses, anticipate future maintenance needs, and allow for better spare parts inventory management giving OEM’s a competitive advantage.

On-board analytics and operator intelligence can mitigate unplanned shutdowns and lost production. Utilizing machine learning techniques and continuous tuning algorithms, servo and robot performance is guaranteed while providing critical diagnostic and maintenance information across the organization.

Analytics and Machine Learning

Remote analytics monitoring enables more effective management of users’ issues, and more importantly enables you to manage your spare parts stores and service resources more efficiently.

Ensure you can meet production and logistics demands and maintain mechanical integrity with Mitsubishi Electric’s advanced analytic algorithms. They continuously tune as well as suppress vibration and sway while calculating tolerance variances to provide prognostic indicators and diagnose impending issues with robotics, ASRS and conveyance machinery.

Ensuring your warehouse and material handling systems are running at peak performance.

Engineering Productivity

The iQ Monozukuri library provides proven applications for material handling machinery and saves hundreds of man hours in PLC and HMI programming and simulation.

Automatic cam profile generation, simplified position compensation, and a standardized code library allow you to get to market faster spending less time on difficult or repetitive tasks… freeing you to innovate more.

Relieving you of routine programming tasks through a library of proven application programs can alleviate up to 80% of original programming, providing a tremendous head start and confidence in code integrity.

Repeatable, and time saving efficiency is what you should expect from your automation provider.

Mechatronics & Robotics

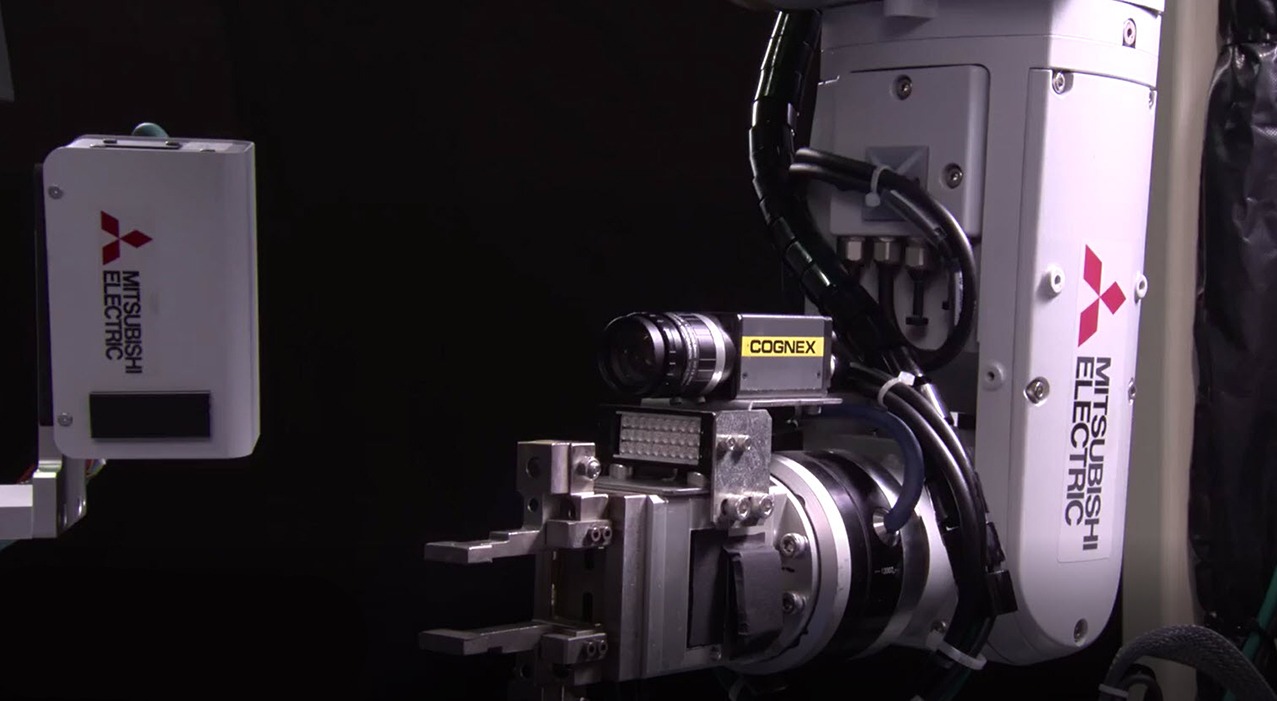

Increasingly, demand fulfillment, E-commerce and manufacturing efficiency relies upon safe, repeatable and accurate motion while processing increasing amounts of tracking and regulatory information.

Integration of machines with robotics presents a unique opportunity to innovate beyond simple handoffs resulting in improved OEE, schedule coordination, seamless production and faster changeovers.

Mitsubishi Electric Automation robotics capabilities integrate quickly and seamlessly with our iQ instruction sets and connectivity to provide a full range of control, motion, robotics and information in a convenient toolkit for OEMs to deploy faster with more consistency and reliability.

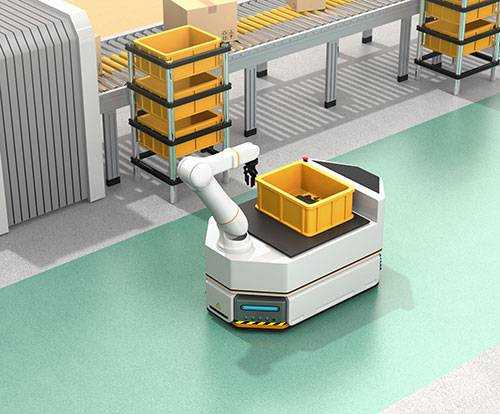

Machine Utilization

Smart machines re-configure automatically, saving you valuable time and money. Evaluating your machines’ Overall Equipment Effectiveness (OEE) will identify areas to improve performance. We provide automation controls to keep machines moving and adjusting with efficiency and precision. To improve utilization, Mitsubishi Electric controls offer the maximum versatility in information and motion processing while integrating with robotics and MES systems.

With ever-changing production needs, your machines should be able to accommodate them at any moment. Mitsubishi Electric’s range of solutions ensure your machines can always adjust to demand.

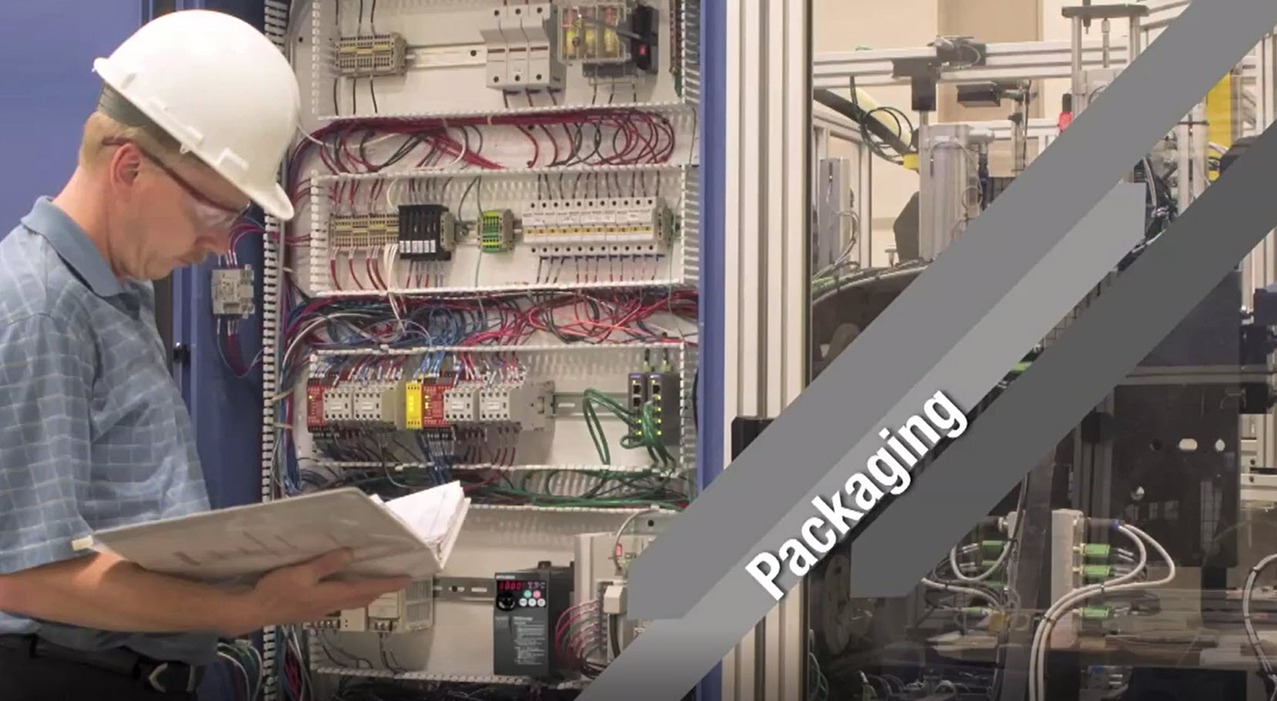

From process to packaging, discrete manufacturing and infrastructure projects, the Mitsubishi Electric portfolio of Control, motion, drives and robotics provides ultra-reliable operations and predictive diagnostics to ensure no lost production

Anti Sway Technology

Mitsubishi Electric’s advanced drive technologies address key safety and operational issues surrounding crane and hoist operations. Whether in industrial or commercial and construction applications, anti sway control is crucial to ensuring loads are moved efficiently and quickly while maintaining safe operating environments. Specific load sensing algorithms set brake outputs on the detection of a falling load and improve start up times through torque sensing and load based speed control.

Using anti sway technology, start up and run times can be optimized without the need for operator input, providing improved cycle times.