Industrial manufacturing robots are popping up in unexpected places, like worlds of vehicle maintenance, autonomous motion planning, and even video games.

Industrial Robots Are Popping up in Unexpected Places

A world of possibilities……

Once the domain of automotive manufacturing, the use of industrial robots is rapidly spreading around the world across a whole range of other industries.

These robots use a variety of advanced technologies, which enable them to:

- Accommodate non-uniform shapes

- Handle variable target positions

- Delineate different colorations

- Precisely coordinate actions

- And even adapt on-the-fly

In other words, they increasingly mimic the intelligence of skilled human operators.

The poster child for Sony craftsmanship and state-of-the-art automation.

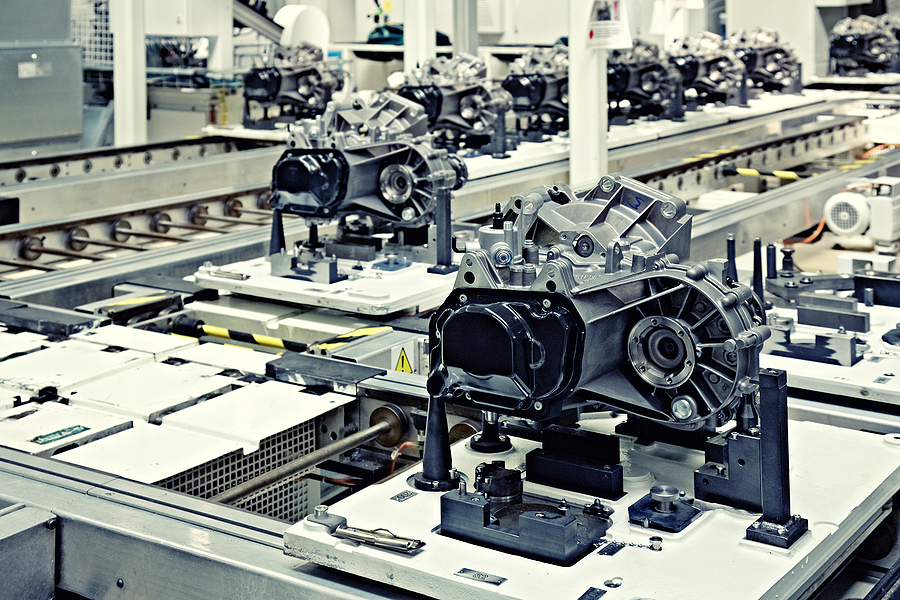

Just across the bay from Tokyo is an unassuming factory in Kisarazu. Inside the small building is a 31.4-meter production line that was completed in 2018. On the line, dozens of robots and just a few humans churn out PlayStation 4 (PS4) consoles. Two people feed bare motherboards to the line. Two additional people package the finished consoles. Everything else is efficiently handled by articulated robots.

Each PS4 console is made with precision. Every part is necessary. PS4 units come off the assembly line at a pace of about one every 30 seconds. The robots attach wires, tape and other flexible parts to the consoles.

The robots deftly handle these materials in a tightly choreographed dance made possible by state-of-the-art industrial robot automation. For example, one robot holds up a flexible flat cable while another twists it, then attaches it in a specific direction using just the right amount of pressure. It’s an extremely complex maneuver for a human, let alone a robot. One of the site’s engineers said, “There’s probably no other site that can manipulate robots in this manner.” Every process is automated. Every move of a robot arm is painstakingly optimized to achieve the best possible return on investment.

The nearly all-automated assembly line benefits from continuous improvements that have been made during the PS4’s successful run. During its lifespan, more than 100 million PS4 consoles were profitably produced. These consoles contributed $93 billion in sales for Sony.

A Change of Pace For Changing Tires

Industrial robots have been used in automotive manufacturing for years, but recently, new applications are appearing in vehicle maintenance as well. A Bay Area-based robotics company, RoboTire, decided to bring robots into the service industry. Its first endeavor? An AI-enabled robot that can change car tires in a fraction of the time a mechanic can.

With this new system, from the time a car pulls-into the garage to the time it pulls-out — is just 15 minutes for a set of four tires. It typically takes around 60 minutes for a human to do the same. Some can go faster, but doing it every day, for eight hours a day, can be stressful and monotonous.

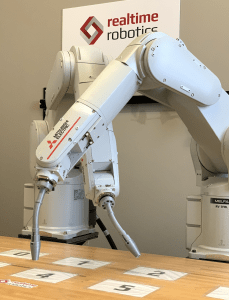

Automating vehicle maintenance is a new frontier. RoboTire teamed up with Mitsubishi Electric to create a robot arm system that could handle the task. It can be easily installed by service centers, dealers and other automotive outlets. Return on investment (ROI) is expected in just over two years.

The use of artificial intelligence (AI) in the robot system prevents impact with the vehicle.

The entire process is brilliantly orchestrated.

- Computer vision and machine learning identify lug nuts for fast removal

- Artificial Intelligence (AI) prevents impact with the vehicle

- Advanced forced feedback sensors prevent lug nut cross threading and guarantees each wheel is safely replaced on the vehicle

Tires are just the beginning. RoboTire believes the possibilities are endless for automating vehicle maintenance. See the system in action in this video.

Removing the Boundaries to Greater Industrial Robot Automation

One of the most exciting developments in industrial robot automation is autonomous motion planning technology. This new multi-robot coordination software from Realtime Robotics eliminates the need to implement cycle-reducing interference zones. It gives robots the ability to recognize and adapt to the other robots in the workcell. It basically automates robot programming. The result? An up to 70% reduction in programming, testing and implementation time.

Robots equipped with Realtime Robotics spatial perception technology function together seamlessly in unstructured and collaborative workspaces. The instant dynamic obstructions are perceived, they evaluate millions of alternative motion paths and choose the optimal route before making a move. It’s all done in milliseconds thanks to Realtime’s advanced sensing perception technology.

The benefits of this new technology are many.

- Smaller footprints because many robots can work closely together

- Higher output thanks to tightly orchestrated and highly choreographed workcells

- Broader application of industrial robots in highly variable automation environments

Realtime Robotics technology empowering two robots to work together.

Because this new technology removes the risk of collisions and simplifies the development cycle, it has the potential to increase productivity while reducing the cost and time to deploy.

We’re tremendously excited about what industrial robots can do today and about all the innovations tomorrow will bring.

*Third party marks and brands are the property of their respective owners.

Automation Solutions Ingredients

Learn more about cost-saving, adaptable robotic solutions from Mitsubishi Electric.

Work with Us and Succeed

We love our customers and the challenges they bring to us. We also like to let our customers shine by discussing how we worked together to solve their biggest challenges. If you have a challenge that needs to be solved and would like to be our next BIG success story, reach out to us and let’s connect!