Mitsubishi Electric helps Rain Bird Corporation expand into profitable new markets

Solution

- FR-F720-00340-NA Variable Frequency Drive

Rain Bird Product Benefits

- More controllable and full-featured than incumbent solutions

- Competitively priced

- Easy package installation vs. onsite “stick build”

Mitsubishi Electric Value-added Advantages

- Customized programming support

- Outstanding product reliability

- Product line breadth and flexibility

BACKGROUND

From the standalone sprinklers in our backyards, to sophisticated watering systems operating on farms, golf courses, corporate campuses, municipal parks, residential developments, shopping centers, sports stadiums and other large landscapes, Rain Bird Corporation is one of the global leaders in the development and manufacture of high quality irrigation products. Founded in 1933, the company is committed to ensuring that the Rain Bird brand and reputation stand for only products of the highest quality and value to its customers in more than 130 countries. Further, while making the world, literally, a little greener every day, the company also does so in the figurative sense as well. Its guiding philosophy, The Intelligent Use of Water™, underpins more than 80 years of innovative development of the industry’s most comprehensive line of water-efficient irrigation solutions, and the company works to minimize outdoor water consumption while preserving the benefits of lawns, plants, trees, gardens and other beautiful natural spaces.

CHALLENGE

One of Rain Bird’s product lines involves the manufacture of booster pump solutions that help customer sites meet their irrigation needs by increasing the pressure of water from the municipal supply or retention ponds in order to obtain optimal coverage from the sprinkler heads. While they have been very successful in supplying pumps for large landscape applications calling for high flow rates, the company realized that they were losing out in many customer applications where lower flow rates of about 100-140 gallons per minute were required. These smaller facilities — often individual commercial or municipal buildings or smaller parks — were frequently selecting “bare bones” pressurizing solutions offered by local irrigation supply companies. These solutions, while low cost, usually provided minimal features, and often were not extensively warrantied. In addition, they were often “stick built” on site, subject to the varying quality of parts and individual installers.

Rain Bird wanted to compete more effectively in these applications, realizing that they could provide a superior option for these customers by providing a higher quality, more fully featured packaged pump station solution backed by the Rain Bird name and reputation. To do so, however, they needed to develop a controllable product at a lower price tier for this market. For assistance in meeting the challenge, they turned to their long term automation solutions partner, Mitsubishi Electric.

SOLUTION

“The products we were competing with just turned on and off like a light switch — they didn’t provide any real control over the watering process,” explained Rain Bird Engineering Manager Brian Hoover. “We thought that if customers could see how much more they could get they would be willing to pay a little more for much greater value.”

The features Hoover and his team wanted to add included energy-saving pressure regulation, which allowed the irrigation system to adapt to the actual energy required rather than running the pump at full speed all the time; a sensor that would shut down the system and trigger an alert if a pipe broke, protecting against flooding; a sensor that would likewise shut down the system and alert the operator in case of a loss of prime, protecting against burn out; and more.

To do all this required a variable speed drive, and for this they looked to Mitsubishi Electric.

“Rain Bird has worked with them for years and their product reliability is exceptional,” said Hoover. “Mitsubishi Electric drives have a very low rate of failure, and if one does fail more often than not we can trace it back to a customer site issue like bad power.”

However, at the time Mitsubishi Electric did not have a product in their line with the specific feature set for the application and marketing situation that Rain Bird was trying to address. So they created one.

“Mitsubishi Electric custom re-coded a VFD to deliver the feature set we wanted,” explained Hoover. “These in-house development capabilities and their flexibility in using them on our behalf is just one example of why we have maintained a relationship with them for so long, why they get first crack at providing a solution for us, and why we have so much confidence in their capabilities.”

RESULTS

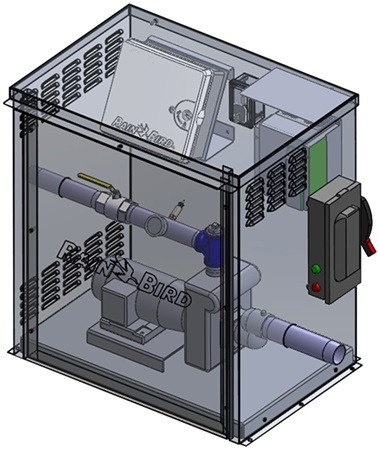

The culmination of this latest partnership effort between Rain Bird and Mitsubishi Electric is a CLP pumping station that delivers a wide variety of features that can help smaller sites reduce their energy and water usage and help protect them from the risk of expensive damage from broken pipes and system burn out — at a price competitive with that of pumping systems offering only basic functionality. In addition, the Rain Bird product is a “package solution” that can be trucked in and installed on site quickly — without the need to build it from scratch on site, saving time and resources.

Hoover reports that, slowly but surely, Rain Bird is beginning to penetrate these smaller market applications that they have been “locked out of” for so long. In fact, they have recently expanded the geographic footprint of where they are offering this new solution to give additional customers access to it, helping to grow this market segment even further for the company.

With Mitsubishi Electric basically creating a new product to help Rain Bird create a new product, Hoover reports that another key reason for Rain Bird’s continuing an ongoing partnership with Mitsubishi Electric has been even further solidified.

“We need to have a relationship with a parts supplier that can provide a single source for all our industrial controls, and Mitsubishi Electric has been able to fill that bill from the smallest element to largest,” he explains. “This gives us the convenience of relying on one high quality source across the board, now more so than ever.”

Become Our Next Success Story

We love our customers and the challenges they bring to us. We also like to let our customers shine by discussing how we worked together to solve their biggest challenges. If you have a challenge that needs to be solved and would like to be our next BIG success story, reach out to us and let’s connect!