IPSUMM’s new flexible, scalable IRIS production cells promise to revolutionize conventional manufacturing processes — with a little help from Mitsubishi Electric

Solution

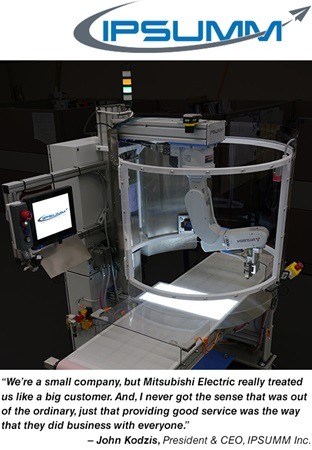

- RV2FBD1S15 6-Axis Robot

- L02CPU-P Programmable Logic Controller

IPSUMM Product Benefits

- Quick switching among diverse manufacturing tasks

- Easy to reconfigure manufacturing capacity

- Scalability reduces capital investment demands

Mitsubishi Electric Value-added Advantages

- Robust programming support

- Timely product availability

- Responsive service

BACKGROUND

Newly expanding to a 18,000 sq. ft. facility in the scenic, bustling seaport city of Portsmouth, New Hampshire, IPSUMM is a growing multi-divisional product development company. IPSUMM’s business units serve the manufacturing sector with equipment and services including die-cutting, capital machinery, automation support and a full service machine shop. According to company President & CEO John Kodzis, the company was built around the idea of helping customers turn any manufacturing idea into a reality.

Recently, IPSUMM’s innovative engineering department was reorganized as a full service engineering firm under the name I2I Engineering. The restructuring will better meet the needs of its own customers, as well as the customers of other IPSUMM divisions. Its newly released flagship product — a unique work cell with the “IRIS” software backbone — is a highly flexible, robot-driven automation solution.

The IRIS backbone allows manufacturers to switch quickly among manufacturing tasks as diverse as picking, painting, assembly, packaging, vision inspection and more, on the same line, with little more than a simple change of a “plug and play” tool and picking a new recipe. In addition, individual IRIS based units can be networked so manufacturers can modify or add capacity cost-effectively as needed, without the risk of “over-investing” in fixed capital equipment.

CHALLENGE

According to Kodzis, the vision for IRIS was actually developed several years ago.

“Go to any factory and you’ll likely see equipment just sitting there idle. Maybe forecasted demand was off or they shifted to a different product mix and those assets are just being wasted,” he explained. “I thought that we could develop production equipment using a different philosophy, making it nearly infinitely reconfigurable. So if you need the line to perform a different function or even make a whole different product, you could do so with existing equipment quickly and cost effectively. Likewise, the system would be modular so you could add or move capacity around without significant capital investment — you could even wheel it elsewhere in the facility.”

IPSUMM built a prototype to prove out this concept of “Taktical Manufacturing,” but, he noted, it took another few years to assemble a team with the right talents to more fully realize this revolutionary vision. Once the team was in place, the challenge became finding an automation partner that had the ability and willingness to help IPSUMM turn their vision into a commercial product. And, according to Kodzis and Engineering Manager Eddie Pflugh, they found that partner in Mitsubishi Electric.SOLUTION

Although they would be utilizing an “off the shelf” robot, the key to the success of the product would be the proprietary IRIS software application that IPSUMM would create. “We had a very different need than most people who just buy a robot; to realize the concept, we would need to revamp the software to control the arm in ways that may not have been envisioned before,” said Kodzis. “Mitsubishi Electric was incredibly helpful in the way that they worked with us, giving us full access to the structure of their robot controller so that we could deploy a lot of the power of their coding in new ways,” added Pflugh. “In addition, if we had a question or issue, they invited us to call them, and their programmers wouldn’t just give us cursory answers — they would really dig in and give us detailed, actionable responses.”

In fact, he noted, the process was kicked off with Mitsubishi Electric sending a programmer highly familiar with the robot to work with IPSUMM’s team side-by-side. “Their responsiveness throughout the whole development cycle was really above and beyond,” said Pflugh. “Whatever resources we needed, they gave us access to the right people at Mitsubishi Electric who were always willing to help.”

Also vital to the success of the flexible work cell, noted Kodzis, was the superior product availability that Mitsubishi Electric is providing. “Usually, getting robot arms quickly can be a really big problem. Sometimes if you order one it can take 10 weeks to get it,” he explained. “But Mitsubishi Electric worked with us on a plan to reduce the initial lead time, and together we are developing plans to reduce that even further as our demand grows.” “We’re a small company, but, overall, Mitsubishi Electric really treated us like a big customer,” Kodzis added. “And, I never got the sense that was out of the ordinary, just that providing good service was the way that they did business with everyone.”RESULTS

The flexible work cell was a market success right away—in fact, according to Kodzis, perhaps even too soon for his preference. “One of the conventional rules of technology is to not sell the prototype, but we started showing the work cell prototype and a customer literally begged us to let them purchase it,” said Kodzis.

Kodzis admits that, although he didn’t love the idea, he finally relented, but not before being allowed to at least work out a few bugs so that IPSUMM could be confident that the customer at least had a “beta” version in their operation.

“That beta unit is still in there, still working great for them,” he said. “They won’t even consider giving it up.” Meanwhile, IPSUMM has moved to produce a fully commercialized “Rev-1” version of the flexible work cell which is now operating in manufacturing facilities around the globe. A more advanced “Rev-2” version—featuring enhanced software architecture and even greater flexibility — is about to be released.

“The product is so flexible that people often ask us ‘can it do this, can it do that,’ but, honestly, a much shorter list would be what it can’t do,” said Kodzis. As much as they are enjoying these successes, Kodzis and Pflugh also have a number of new innovations in the wings. And, as they develop them, they say, they would never hesitate to call in their recent partner to help out in any way they could. “Mitsubishi Electric has a great product and great service and they’ve been fantastic at helping us meet the industry needs that we were targeting with the flexible work cell,” said Pflugh. “And there will undoubtedly be many more times in the future where they will be the clear solution as well.”

Become Our Next Success Story

We love our customers and the challenges they bring to us. We also like to let our customers shine by discussing how we worked together to solve their biggest challenges. If you have a challenge that needs to be solved and would like to be our next BIG success story, reach out to us and let’s connect!